News

Contact Us

Service telephone

+86 0391-8299688

Email:LeruiTools@hotmail.com

Address:No. 99, East Wengong Road, High-tech Industrial Development Zone, Xiguo Town, Mengzhou City, Jiaozuo City, Henan Province, China

Sales Manager

+86 18303902299(Mr. Liu)

Sales Engineer

+86 16663799288(Mr. Li)

LERUI tool grades and application range, selecting the corresponding grade can improve efficiency

Lerui CBN tools are suitable for many industries, and the CBN content of different grades is different. Now the grades and processed materials are sorted. Please purchase the corresponding tool to improve processing efficiency and prolong tool life.

| LERUI Welding high-performance CBN material applications | ||||

|

Processing category |

Recommended CBN grades |

CBN content | Cutting state | Subdivision of processed materials |

| K Cast Iron | LBN9307 | 85%/90% | Continuous to strongly interrupted machining | Cast iron, alloy cast iron, hardened steel, powder metallurgy |

| LBN9503 | Cast iron, alloy cast iron, powder metallurgy | |||

| LBN9300 | Alloy cast iron, powder metallurgy | |||

| LBN8500 | Cast iron, alloy cast iron | |||

|

H Interrupted machining of hardened steel |

LBN7107 | 60%/75% | Continuous to Light Interrupted Heavy Interrupted Machining of Hardened Steel |

Continuous and interrupted cutting, hardened steel, valve seat machining, CV joint applications |

| LBN7303 | Hardened steel, moderately to heavily interrupted cuts | |||

| LBN7507 | Hardened steel with hardness greater than HRC45 | |||

| LBN7500 |

Hardened steel with hardness greater than HRC45 Hardened steel for moderate to heavy interrupted cuts |

|||

|

H Continuous machining of hardened steel |

LBN5301 | 40%/55% | Continuous to lightly interrupted machining of hardened steel |

High-speed cutting continuous, light interrupted cutting quenched steel with excellent roughness |

| LBN5302 |

Continuous, lightly interrupted cutting, case hardened steel, fully hardened steel and ductile iron |

|||

| LBN5501 |

High-speed cutting continuous, light interrupted cutting of hardened steel |

|||

| LBN4000 |

High-speed cutting continuous, light interrupted cutting quenched steel, case hardened steel has better roughness |

|||

|

S difficult-to-machine materials |

LBN9307 | Refer to the above description for the same material |

Good versatility for turning, milling alloy cast iron, hardened steel, valve seat alloy powder metallurgy, etc. |

|

| LBN5302 |

Ductile iron, powder metallurgy, continuous high-speed machining hardened steel |

|||

| LERUI Application of polycrystalline CBN materials | ||||

|

Processing category |

Recommended CBN grades |

CBN content | Cutting state | Subdivision of processed materials |

| LBN930 | 88%/93% | Continuous to strongly interrupted machining of chilled cast iron |

Cast iron, alloy cast iron, hardened steel with hardness greater than HRC45 |

|

| LBN900 | 85%/90% | Continuous to strongly interrupted machining of cast iron | Cast iron, alloy cast iron, ductile iron | |

| LBN750 | 70%/75% | Continuous to Interrupted Machining of Hardened Steels |

High-speed cutting continuous, light interrupted cutting hardened steel, high chromium cast iron |

|

| LBN650 | 60%/65% | Continuous machining of hardened steel |

Ductile iron, continuous high-speed machining hardened steel |

|

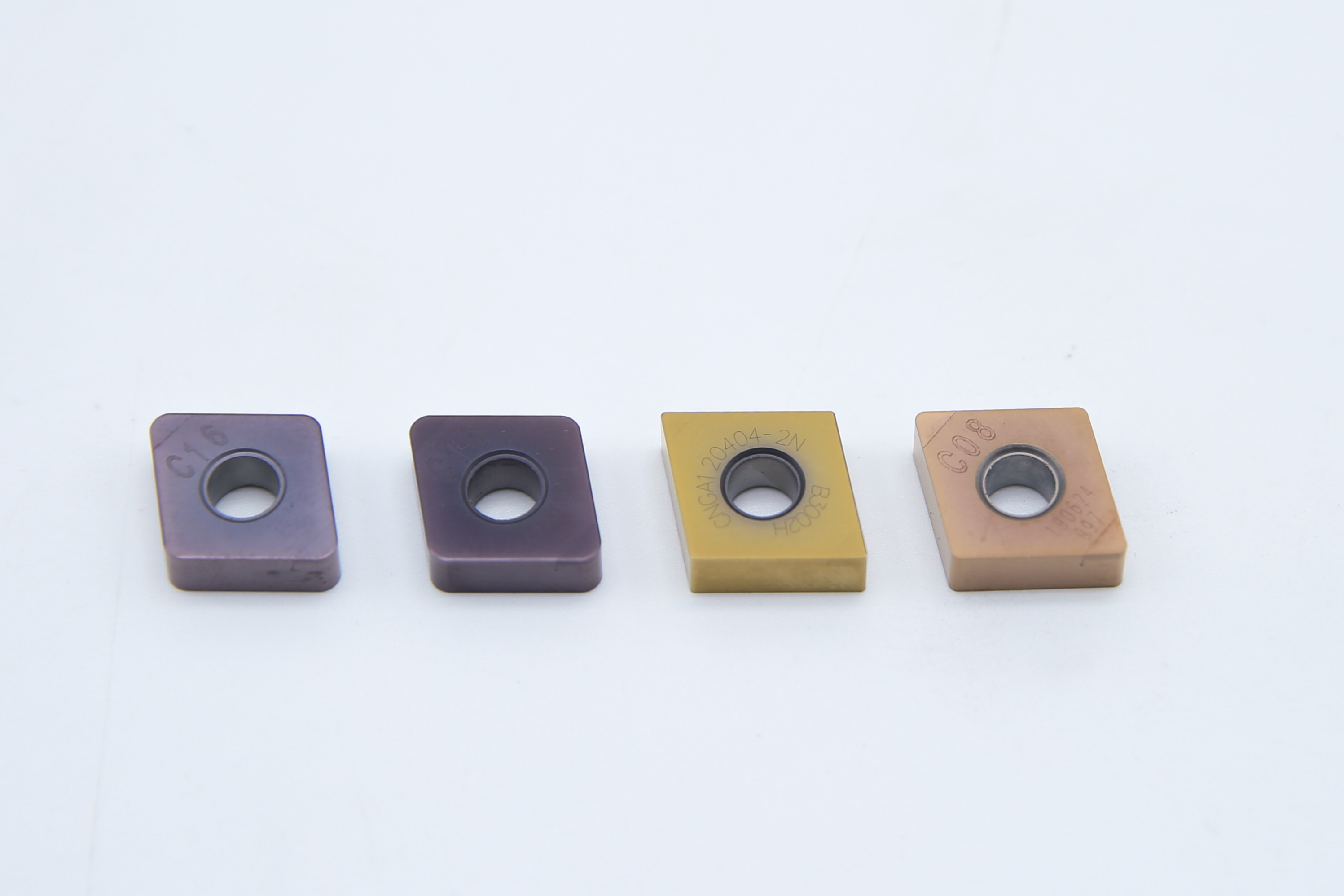

| LERUI Application of CBN Nano PVD Coating | ||||

| Coating application areas | CBN coating grade | color | material | Coating Features |

| cast iron | TC50 | dark grey | AlCrN |

Super strong bonding force, efficient cutting to achieve extended cutting life |

| hardened steel | CA70 | rose purple | TIAlN |

Fine film layer, excellent surface roughness and stability |

| heat resistant steel | NS80 | Bronze | TiSiN |

High temperature resistance and high speed, high temperature cutting stability is very long |

| Ductile Iron | QC30 | silver | TiCrN |

Self-lubricating film layer, excellent heat resistance and wear resistance |

Coated PCBN Inserts

Coated Pcbn Inserts

Honing Head

Honing Head

Diamond/CBN Honing Stone

Diamond/CBN Honing Stone

LBS series tipped PCBN turning inserts

Tipped Pcbn Turning Inserts